Gas turbine engines operate at peak performance when compressor blades and stators are clean. However, compressor components become fouled over time as air contaminants build up on airfoil surfaces. As fouling increases, the compressor efficiency, thermal efficiency, and power output decrease and specific fuel consumption increases. For this reason, compressor water wash to remove contaminants is a standard maintenance procedure for gas turbine engines. About every six months, while offline, each plant will open ports on top of the compressors, and while the turbine is slowly turning, spray the blades with a strong soap solution. After allowing to set for about an hour, the compressor blades are rinsed with clean water. To remove the soap and water, along with the dust and dirt, two or more drain valves are installed on the lower side of the compressor. These are called water wash drain valves.

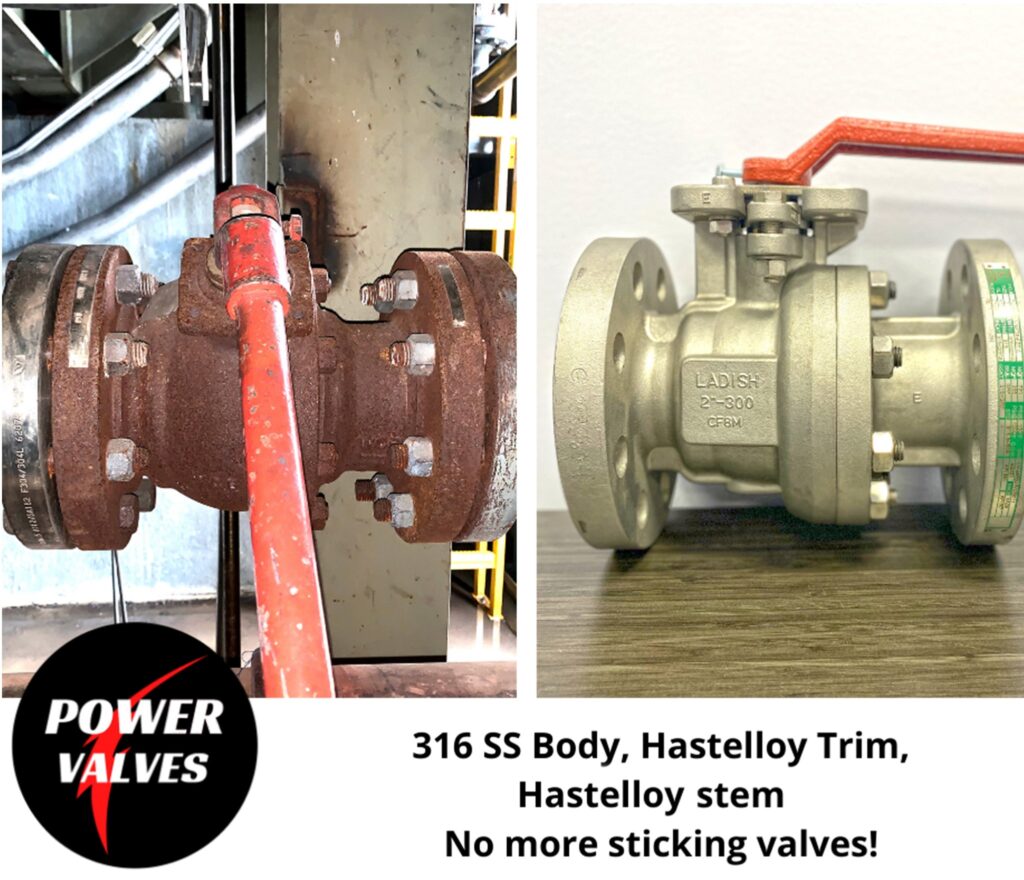

These valves are typically 2” and 4″ manually operated ball valves, which are only open during maintenance and water wash. They are rarely stroked under pressure. Original equipment in many plants were JC Trueline ball valves.

The problem with this application is that most plants don’t flush with enough water to rid the system of the soap and dirt, so some of the soap and dirt get closed in the valves. The plant then runs for 6 months, and the valves are located just below the CT. Temperatures under the CT can easily get to 200 F or more if the valves are holding tight, and up to 800 F if the valves are leaking. This cooks whatever is in the valves. Then, when they need to stroke them open, the valves stick. Typical failures include stem twisting and ball-slot deformation.

Power Valves LLC, working with Ladish Valves, has developed a solution which includes a 316 SS bodied ball valve with Hastelloy ball and seat, both coated with Chromium Carbide. We upgraded the stem to Hastelloy and the packing to graphoil. These Ladish valves are more expensive than the OEM valves, but they work and solve the problems. The valves will stroke without using a cheater or loosening the body bolts, they hold tight shutoff, and the stems do not twist.

Call today for a Quote!